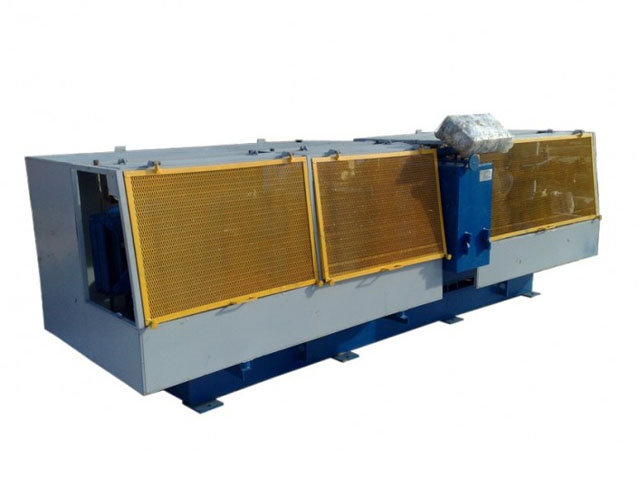

691C integrated lathe is designed for processing of round undersized trees into rounded logs with a long groove for blockhousing, matched three-edged round cants, beams, floorboard and clapboard blanks, edge board of various sections.

Dimensions of a finished product with allowance for further processing (shrinkage) and tolerances are determined by the customer when ordering.

The price of 691C lathe includes one outfit for one type of lumber. Outfits for other above-listed lumber types are to be ordered additionally.

A log can be cut into precise dimensional lumber of a good surface quality just in a single run. The log undergoes three processing operations: rounding, smoothing and cutting.

691C lathe Specification

| Maximum butt end diameter of processed log, mm | 240 |

| Minimum log length, mm | 1800 |

| Feed rate, m/min | 0 - 8 |

| Element diameter after rounding, mm | 70-160 |

| Dimensions of saws installed, mm | |

| Register diameter | 50 |

| Outer diameter | 450(500) |

| Rotation frequency, rpm: | |

| Rounding head | 1100 |

| Cutters | 2925 |

| Saws | 1450 |

| Drive power, kW: | |

| Feed | 1,1 |

| Rounding spindle | 22 |

| Saws | 30 |

| Cutters | 2x7,5 |

| Dimensions, mm: | |

| Length | 3036 |

| Width | 1410 |

| Heigth | 1280 |

| Weight, kg | 3000 |

Distinctive aspects of machine design and furnishing

– Frequency converter for smooth feed rate adjustment.

– High quality bearings of the rounding unit.

– Three sets of cutting tools for the rounding unit.

– One set of outfit.

691C lathe main units

Rounding unit

Rounds a rough log, i.e. after the log passes this unit, it is rounded to various diameters (from 70 to 160 mm) calibrated along its length.

Rounding and cutting units

After the rounding the element obtains a center line that remains unchanged throughout the procedure. Thus the upper and lower cutter will be symmetric about the center line.

Cutting unit

This unit processes the element from up and down to obtain a desired shape in accordance with the cutting chart.

Sawing unit

This unit cuts the element into finished dimensional lumber depending on the cutting chart. When log structures are produced, this unit is disabled.

Assembly and installation

The installed lathe should be easily accessible and well-lighted. The lathe is installed on a foundation with the depth depending on the ground type but no less than 600 mm and attached to the foundation by six 16 mm anchor bolts. After the installation onto the foundation the lathe is leveled. The level is mounted onto the foundation. Maximum allowable horizontal deviation is 0,2 mm along 1000 mm. The foundation is then cemented and consolidated; then the anchor bolts are tightened.

Additional information on 691C lathe

1. Warranty

The manufacturer provides a 1 year warranty for all equipment

2. Assembly and maintenance

All machines are equipped with cutting tools (excluding saws, as 691C can use saws of various manufacturers at the user’s discretion. Saw specifications are listed in the Equipment Certificate). An additional agreement for commissioning and start-up may be concluded.

3. Moisture of raw materials

This machine is designed for processing of round softwood and hardwood trunks of 3rd grade and above as per GOST 9463-72; GOST 9462-71.

4. Spare parts

The Customer forwards an order for additional equipment or spare parts required, upon its receipt the Seller determines manufacture and delivery time.

5. Machine manufacture time

Machine manufacture time is within 1-1,5 months.

6. Payment terms

50% advance payment and 50% when the equipment is ready for shipment. 3% discount may be granted for 100% advance payment.

7. 691C approximate capacity

Using 0,72 utilization rate for calculation:

– Minimum: 830 running meters per shift;

– Average: 1 900 running meters per shift;

– Maximum: 2 765 running meters per shift.

8. Waste

Chips (after rounding, non-pulp – with bark),

Scrap (after smoothing),

Sawdust (after cutting).

9. Sawdust disposal

Two types of sawdust disposal depending on production facilities are considered (not included into machine price):

– scraping conveyor (preferable);

– pneumatic conveying.

10. Dimensions of materials processed

691C lathe is a feed through machine, so the maximum length of a log is of no importance, the only limitation is butt end diameter which should not be over 240 mm. Minimum log length is 1800 mm.

The lathe is equipped with the following tools:

| Lathe make | Rough knife | Finishing knife |

|---|---|---|

| 691C (rounding) | 2 | 2 |

| 691C (smoothing) | 4 | 4 |

Output variants for 691C integrated lathe for undersized trees processing:

Output sets include:

– 2 cutter housing assemblies;

– knife sets;

– a set of saw blades with flanges;

– rollers for individual cutter layouts (half-blockhouses, floorboards);

– laminated cloth supports (where provided);

– multipurpose roller bushings.